Main Menu

- Home

- Products

- Applications

- Product Support

- Service

- Learn

- Product News

- About Us

- Contact Us

Do you suspect your workers are being harmed by excessive noise? A walkaround site survey is the first step to addressing

this issue. Take individual decibel level measurements at discrete locations in your facility during typical operation. This important process can help answer these questions:

Do you suspect your workers are being harmed by excessive noise? A walkaround site survey is the first step to addressing

this issue. Take individual decibel level measurements at discrete locations in your facility during typical operation. This important process can help answer these questions:

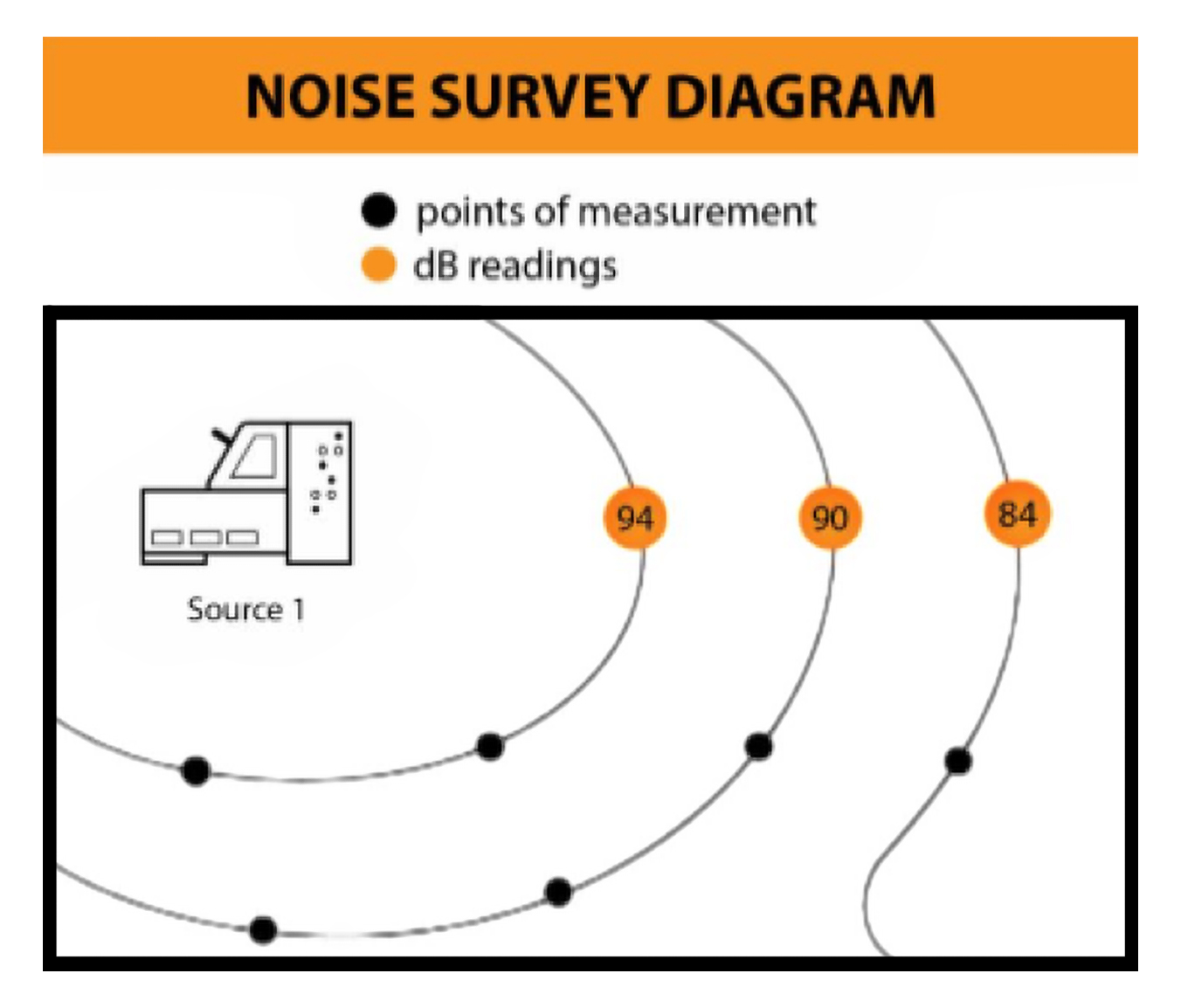

If this simple walkaround measurement indicates potential problems (levels greater than 80 dB), a more systematic plant sound survey may be needed. As a part of the survey, potential problem areas can be plotted on a noise survey map (also known as a sound map or occupational noise survey). This can be as simple as using an existing site map and hand noting the decibel level of each location measured.

Limits for noise exposure vary across the world. Please use resources appropriate for your location when seeking out specific standards. In general, OSHA regulations set the legal limit for exposure at an average of 90 dBA over an 8 hour day. However, there is ample evidence that lower doses of noise can damage hearing.

If any areas of a plant are identified as having noise levels over 80 dBA,

consider getting a clearer picture of the noise exposure to individual workers using Noise Dosimeters. These are small noise measurement devices worn by a worker for a typical work shift. Learn more about noise dose measurements.

If any areas of a plant are identified as having noise levels over 80 dBA,

consider getting a clearer picture of the noise exposure to individual workers using Noise Dosimeters. These are small noise measurement devices worn by a worker for a typical work shift. Learn more about noise dose measurements.

When developing a plan for mitigating the effects of noise, consider the following