The Model 831 sound level meter can be used with the 378A04 low noise microphone & preamplifier to measure noise levels as low as 6.5 dB A-weighted. This FAQ describes the necessary equipment and procedure for setting up the Model 831 to make these measurements.

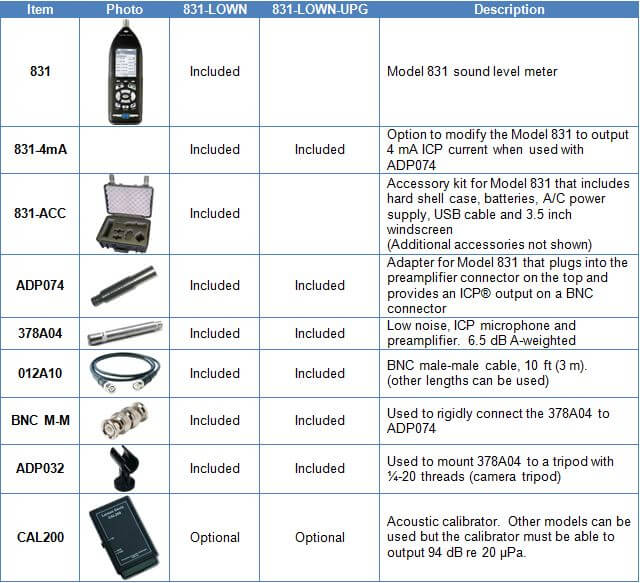

Required Items

A complete kit with all these items can be ordered using part number 831-LOWN and an existing 831 can be upgraded using part number 831-LOWN-UPG.

Fully assembled, the 831-LOWN system looks like the systems shown below depending upon whether the flexible BNC cable is used or the rigid connector.

Important Information

Important Information

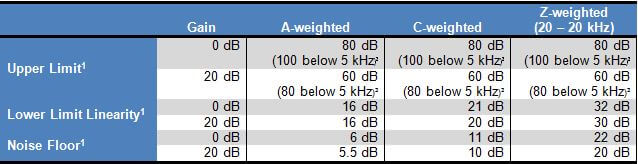

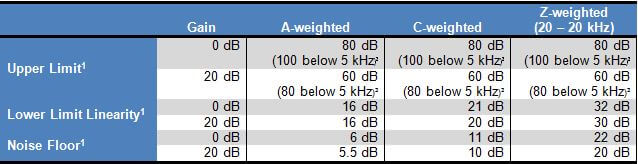

When using the 378A04 with the Model 831, the overload indication will not work properly because the 378A04 has less dynamic range than the Model 831. Measured levels above the Upper Limit documented below should be considered as overloaded. The table below documents the acceptable measurement range.

1Typical values2The frequency dependent 3 % distortion limit is 80 dB for the entire frequency range and 100 dB from 10 Hz to 5 kHz.3The frequency dependent 3 % distortion limit is 60 dB for the entire frequency range and 80 dB from 10 Hz to 5 kHz.

1Typical values2The frequency dependent 3 % distortion limit is 80 dB for the entire frequency range and 100 dB from 10 Hz to 5 kHz.3The frequency dependent 3 % distortion limit is 60 dB for the entire frequency range and 80 dB from 10 Hz to 5 kHz.

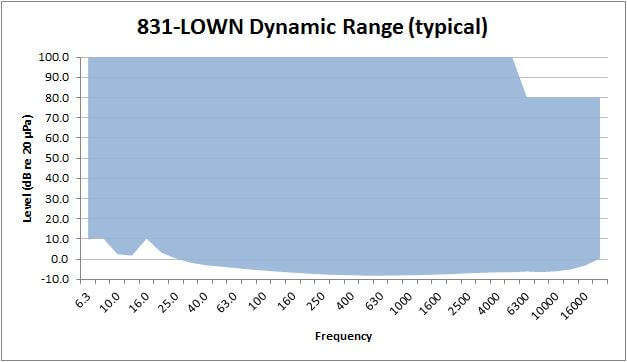

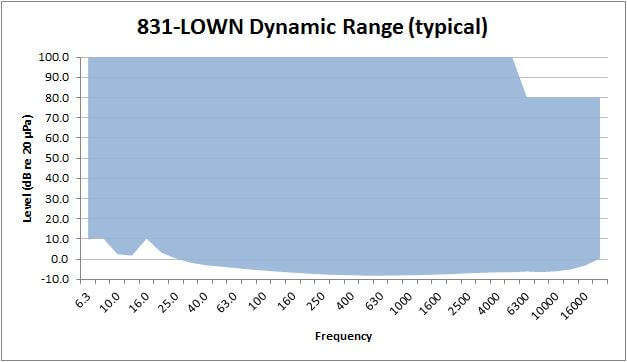

The typical dynamic range for an 831 with 378A04 is shown below

Spectral Statistics

Spectral Statistics - The Model 831 records statistical distribution data (LN) between 200 and 0.2 dB. Statistics for levels less than 0.2 dB are not computed. This does not impact the broadband statistics but has potential to be seen in spectra statistics.

Power and Battery - Using the 378A04 with the Model 831 will decrease the battery run time by approximately 15%.

Standards compliance - The Model 831 sound level meter when used with the 378A04 low noise microphone has not been tested for compliance with IEC 61672-1 or ANSI S1.4. Larson Davis does not guarantee compliance with all the requirements of IEC 61672-1 or ANSI S1.4 when using the Model 831 with a 378A04 microphone.

Factory Calibration or Certification

Because of the technology used to build the 378A04 it is not possible to perform an annual certification of the 378A04 using an electrostatic actuator, which is commonly used by calibration facilities. For this reason, annual calibrations should be performed at the factory in an anechoic environment. Contact Larson Davis for price and lead time information.